Technology

Visual NavigationVisual Navigation

Advanced vision technology provides high self-position recognition capabilities.

Using QR codes attached to walls and ceilings, self-position is estimated by 3-point measurement.

Vehicle positioning accuracy achieves ±10mm. (No magnetic tape, magnetic bars, or laser reflectors required)

AdaptabilityAdaptability

High adaptability through pallet position correction function, capable of handling pallets with misaligned positions and angles.

High positioning accuracy, sensing accuracy, and control algorithms enable response to high-rise, multi-level, and multiple sizes.

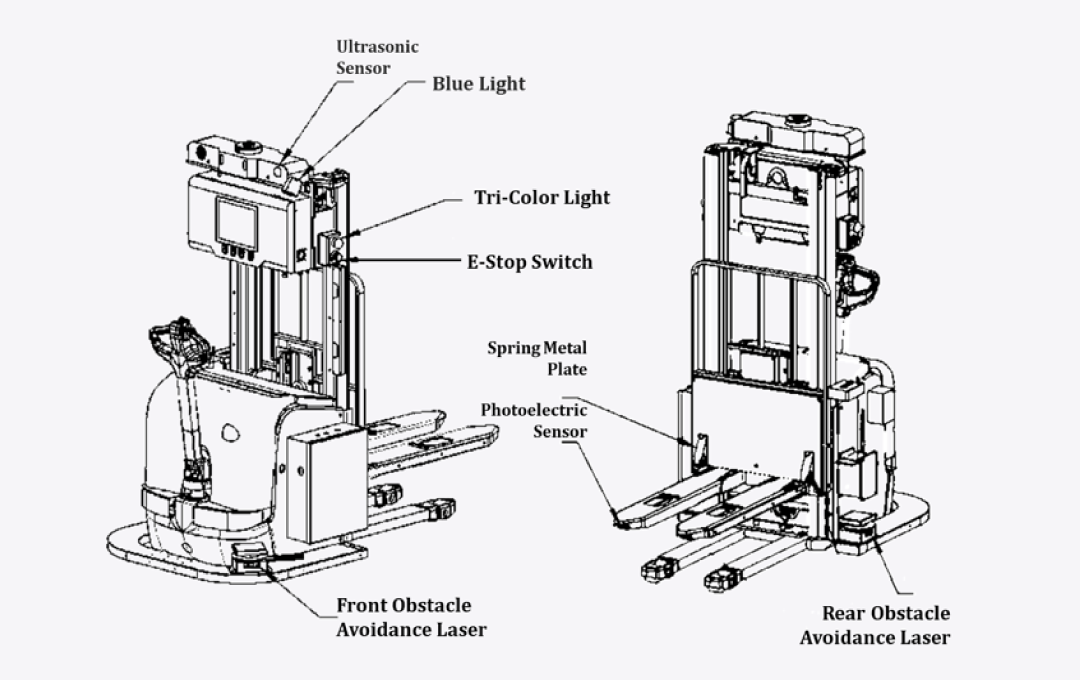

SafetySafety

High safety is achieved through a combination of LIDAR, ultrasonic, photoelectric sensors, and bumper sensors.

Furthermore, some models comply with the latest ISO3691-4 2020 standard.

※CE certification has been obtained as AGF along with ISO3691-4

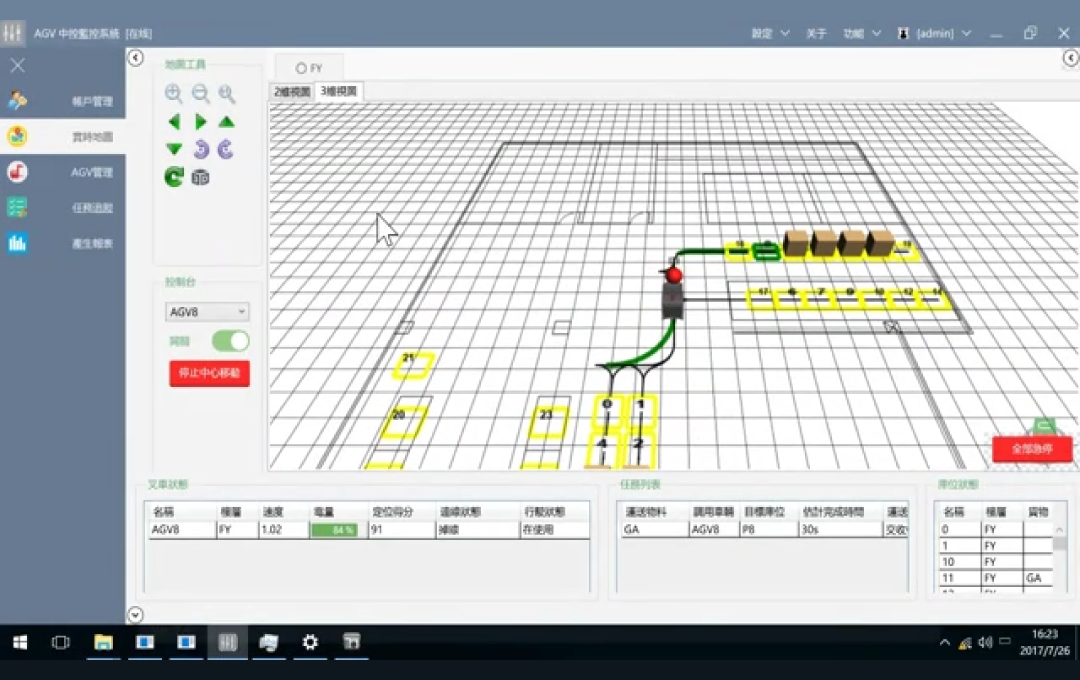

EfficiencyHigh Efficiency

Our proprietary Robot Control System (RCS) performs communication control and task allocation with more than 150 AGFs, featuring functions such as multi-vehicle scheduling, travel route planning, collision prevention, task management, and data analysis.

It also integrates with systems such as MES/WMS/ERP to achieve optimal operation.

Digital ManagementDigital Management

Combined with the Okaya Steel Group's extensive experience and know-how in factory logistics automation and Okaya System's WMS (Warehouse Management System), we achieve further "automation" and "visualization" of logistics sites.

WMS (Warehouse Management System) "Logitite" (okaya-system.co.jp)